최근 검색어가 없습니다.

기록전체 삭제

파이픽스만의 전문적인 기술로 특별 한 성과를 이루고 있습니다

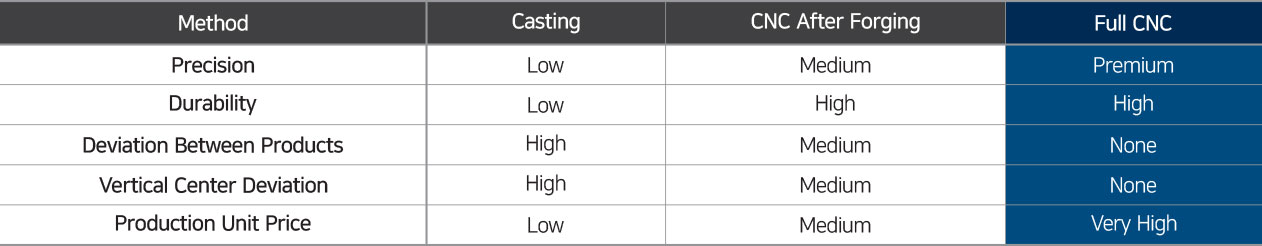

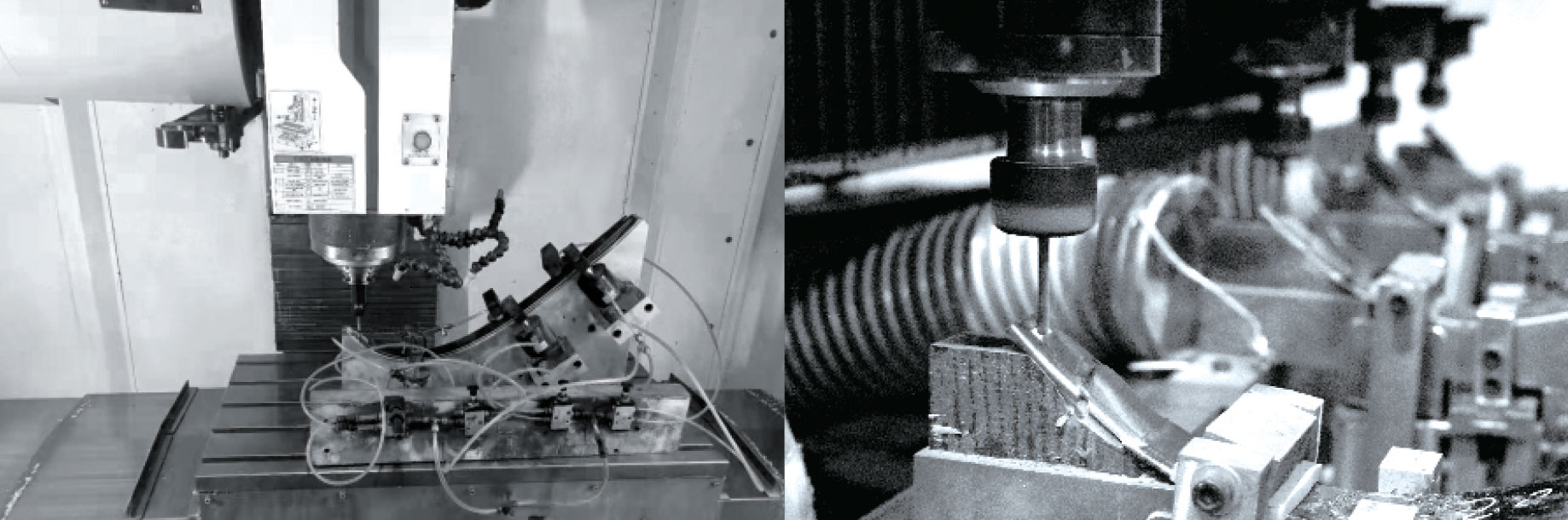

The construction method of the archery riser includes casting, forging, CNC (forging), or the full CNC method, which is made by cutting a solid block of aluminum with a CNC machine tool.

The casting method most commonly used for low-cost risers has an advantage of easily mass-producing products using magnesium and aluminum materials, but has a disadvantage of inaccuracies generated during the casting process which can reduce one's shooting accuracy.

The forging method, which is made by tapping hot metal, creates a higher precision and stronger product than casting but at a higher price.

Full CNC is made by cutting a solid block aluminum with a CNC machine tool, so production is limited and the cost of the process is high. Some manufacturers do not release Full CNC products due to profitability.

However, as Full CNC has a precision of 1/1000mm, the product is vastly superior to that of casting and forging. Each product is perfectly centered at the vertical and there are no deviations between products.

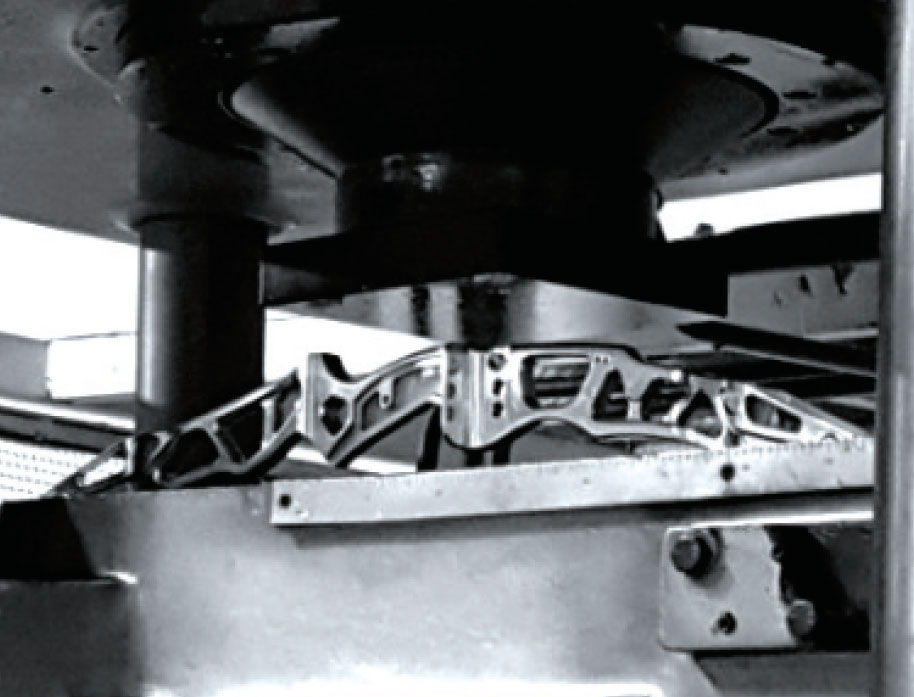

The most precise and stable washer limb alignment system in the world with

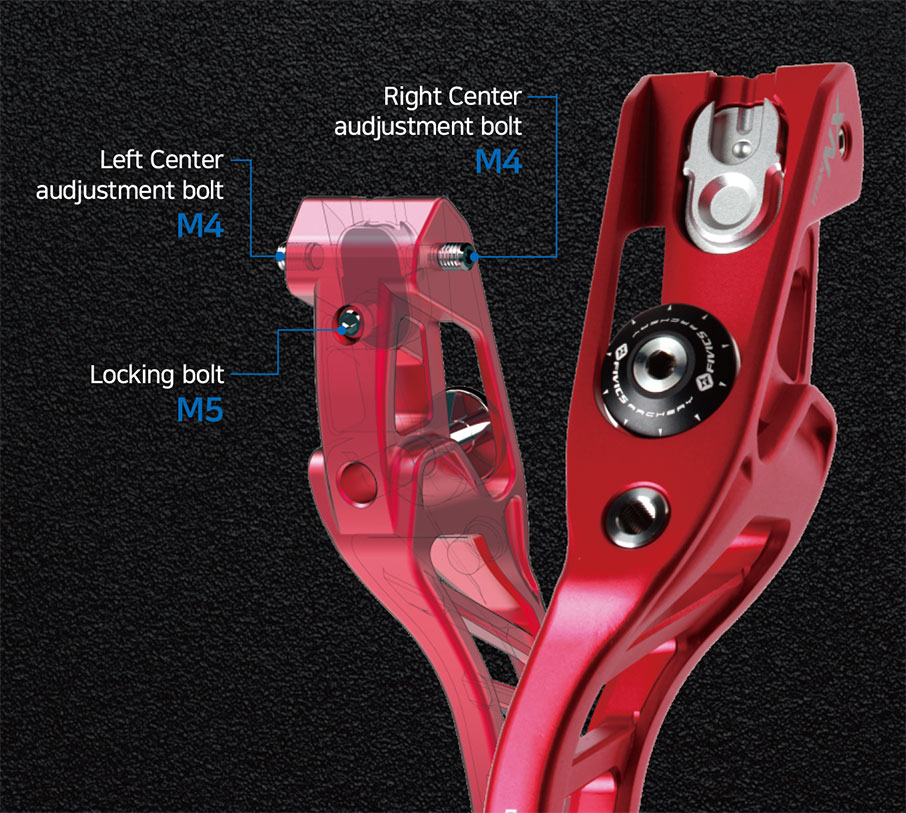

INCREMENTS AS LOW AS 0.05mm

Normally, limb alignment adjustment with the washer system is able to adjust in 0.1mm increments. FIVICS' ultra-precise limb alignment system can adjust 0.05mm to 0.15mm, offering double the amount of precision.

Adjusting the limb alignment without removing the limbs

EASY & STABLE CENTER AUDJUSTMENT

- Perform bow center adjustment without disassembling the riser and limb alignment system.

- The limb alignment system allows a strong fixing force with only one locking bolt.

Limb Alignment System

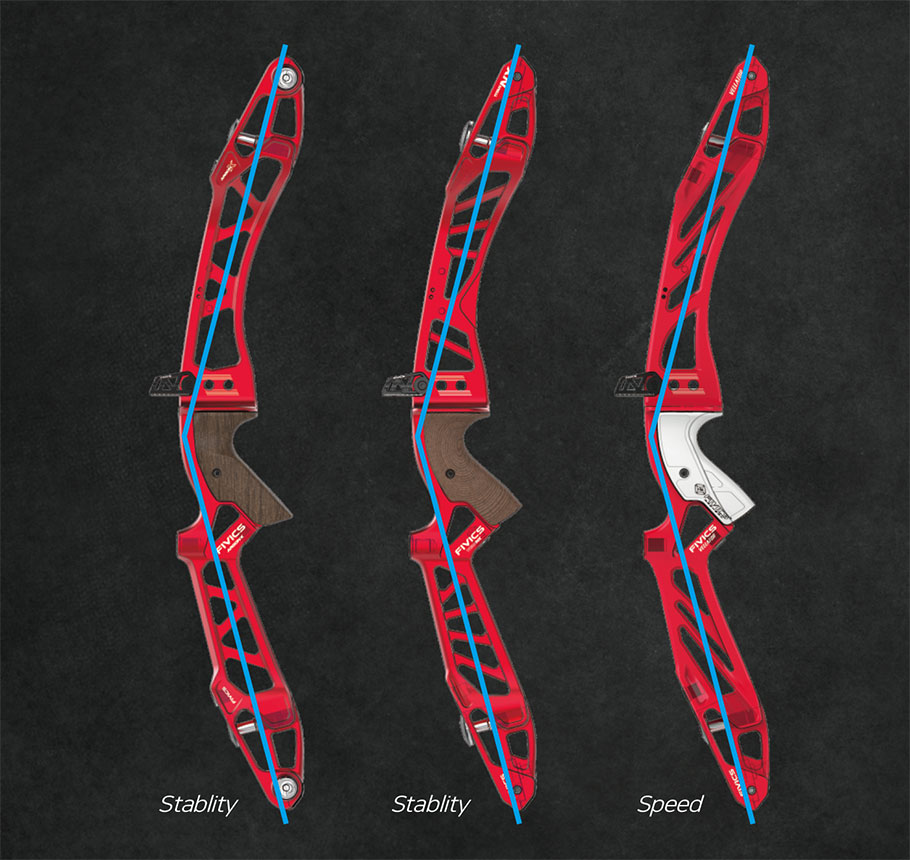

The new FIVICS risers are designed with a stable low center of gravity, creating significantly less vibration and shake than a normal riser during shooting.This also has the added benefit of the bow falling faster after the shot, which increases the arrow speed and reducesaccidental influence that may be caused by minute hand movement.

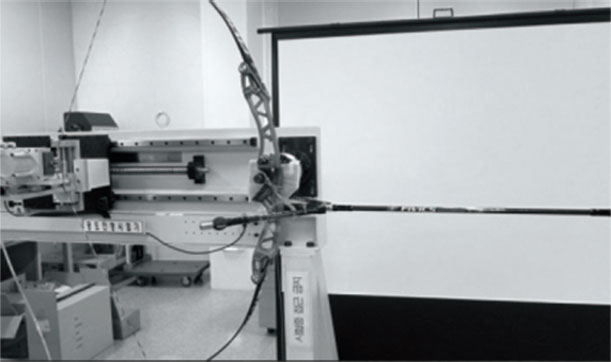

7075 RISER VS EX 6061 RISER

The Titan EX riser is designed with 6061 aluminum to allow for the best vibration absorption possible. Using a hydraulic press machine, we have scientifically proven that our 6061 aluminum risers can tolerate higher pressure than risers made from more rigid materials such as 7075 aluminum.

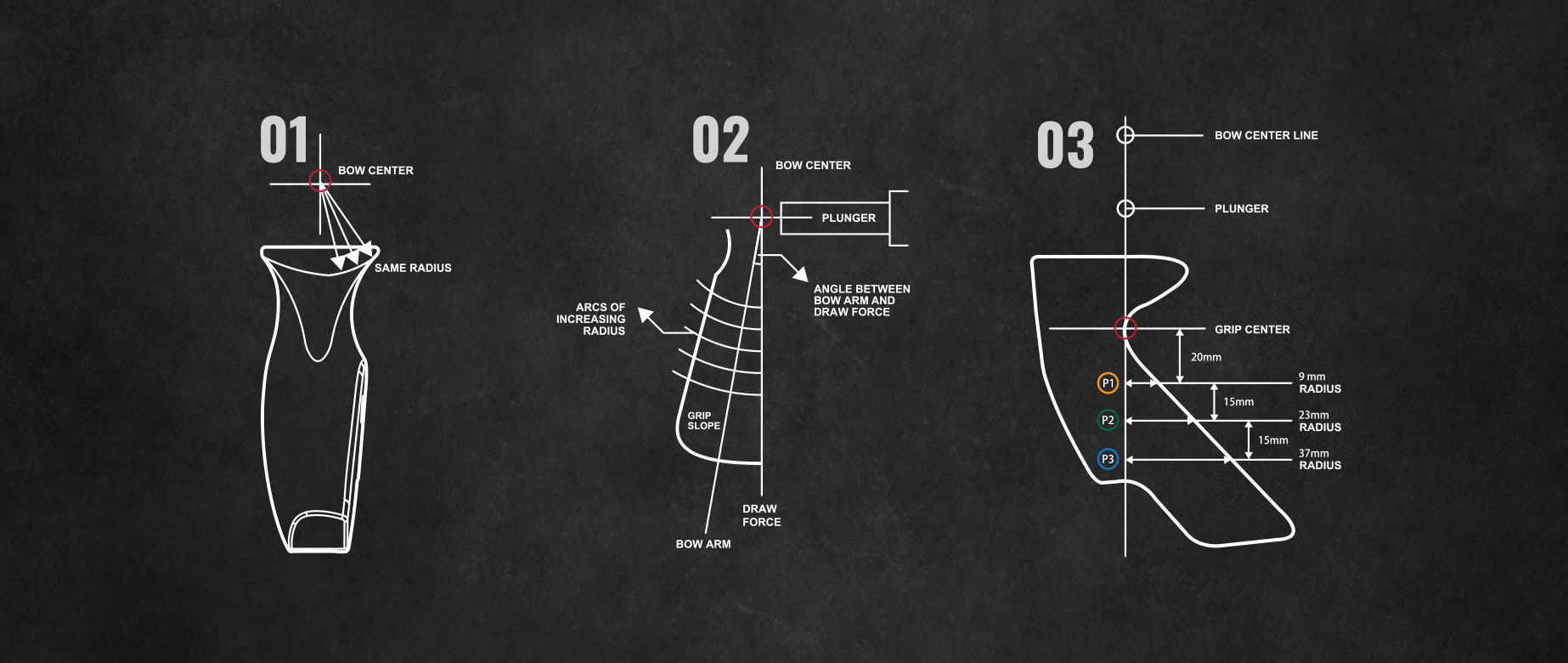

3 important points in grip system

TIGHT AND SECURE GRIP

FIVICS' TSG (Tight and Secure Grip) is designed to maximize the contact between the archer's bow hand and the grip. This grip was produced in an optimal shape specializing in close contact by analyzing the close contact between the hand and the grip in three dimensions as well as analyzing the direction of the force received by the bow hand during anchoring. The FIVICS TSG is combined with FIVICS' STABLE & STEADY GEOMETRY Riser to exert a synergistic effect which promotes the bow to move to the target at a faster speed and allows a stable control of the arrow even at high speeds.

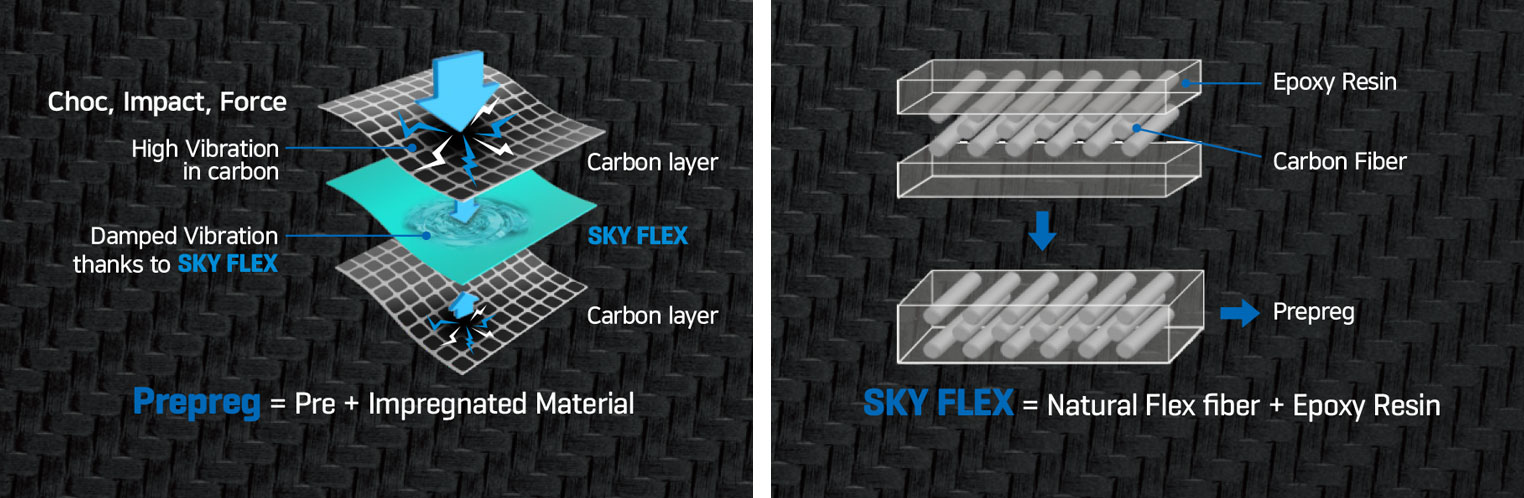

All FIVICS line Limbs

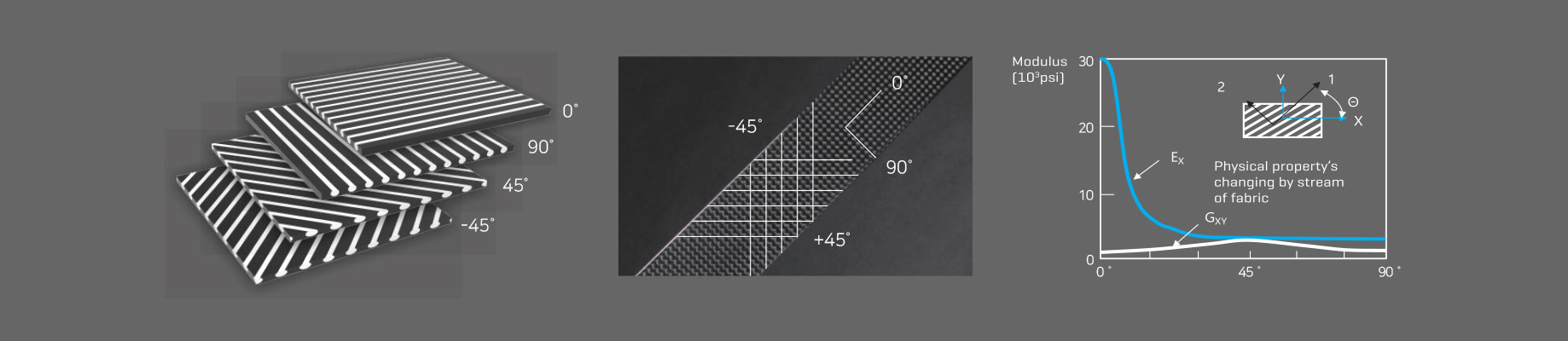

CWP CARBON PREPREG MATERIAL

With the cooperation of Fivics Archery and SK Chemical, we have developed a unique Carbon "PrePreg material" specifically designed for the highest performance in archery. This material allows efficient pull kinetics and quick restoration.

- The most important part of an archery limb is the carbon's raw material.

- In the process of producing good carbon materials, prepreg technology of epoxy and carbon fiber is proportional to the tension and torsion of the limbs.

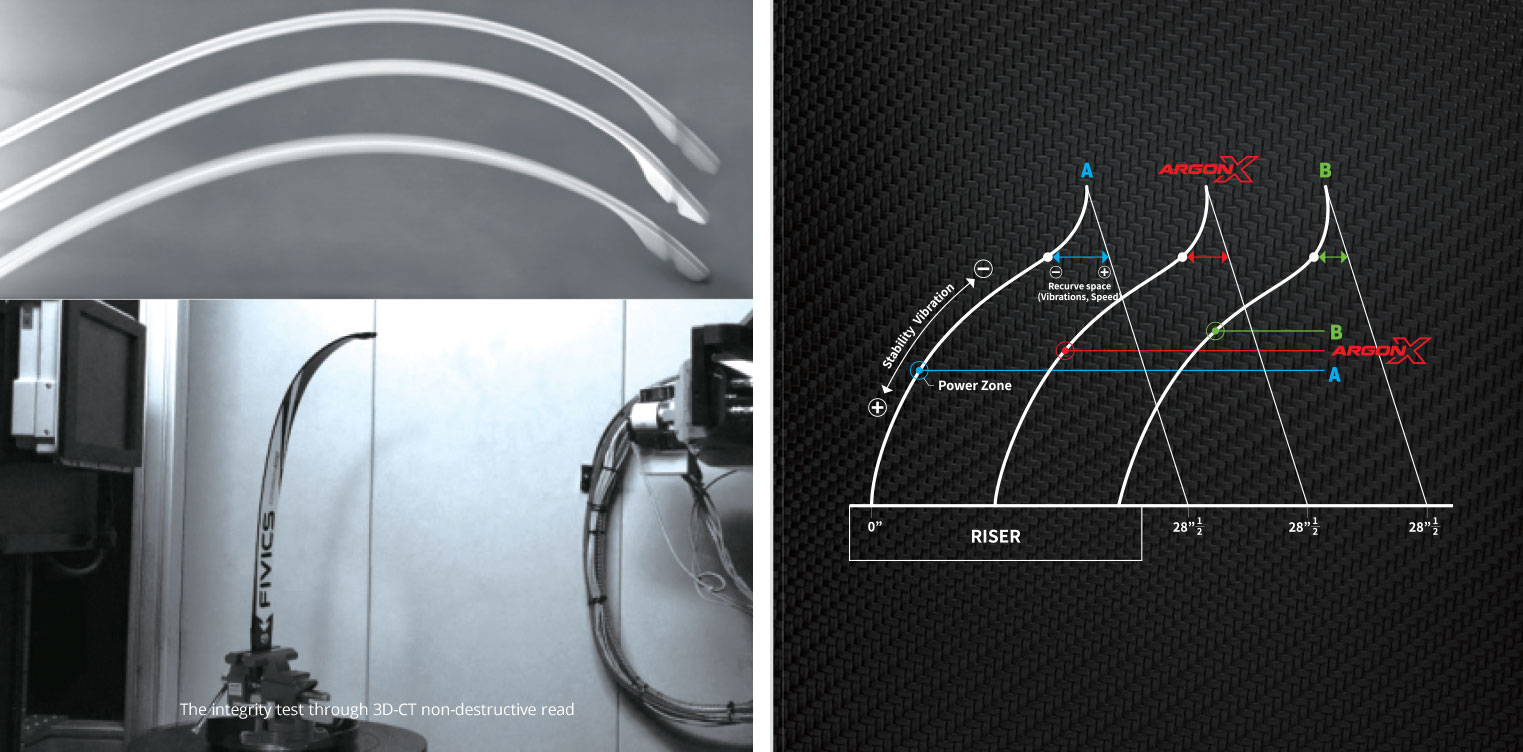

New type of Limbs Argon X - Surprising eFFEct of

45 CARBON TECHNOLOGY

New type of Limbs Argon X - Surprising eFFEct of

POWER ZONE BALANCE

The location and angle of the Power Zone has been improved (area that creates the most acceleration)

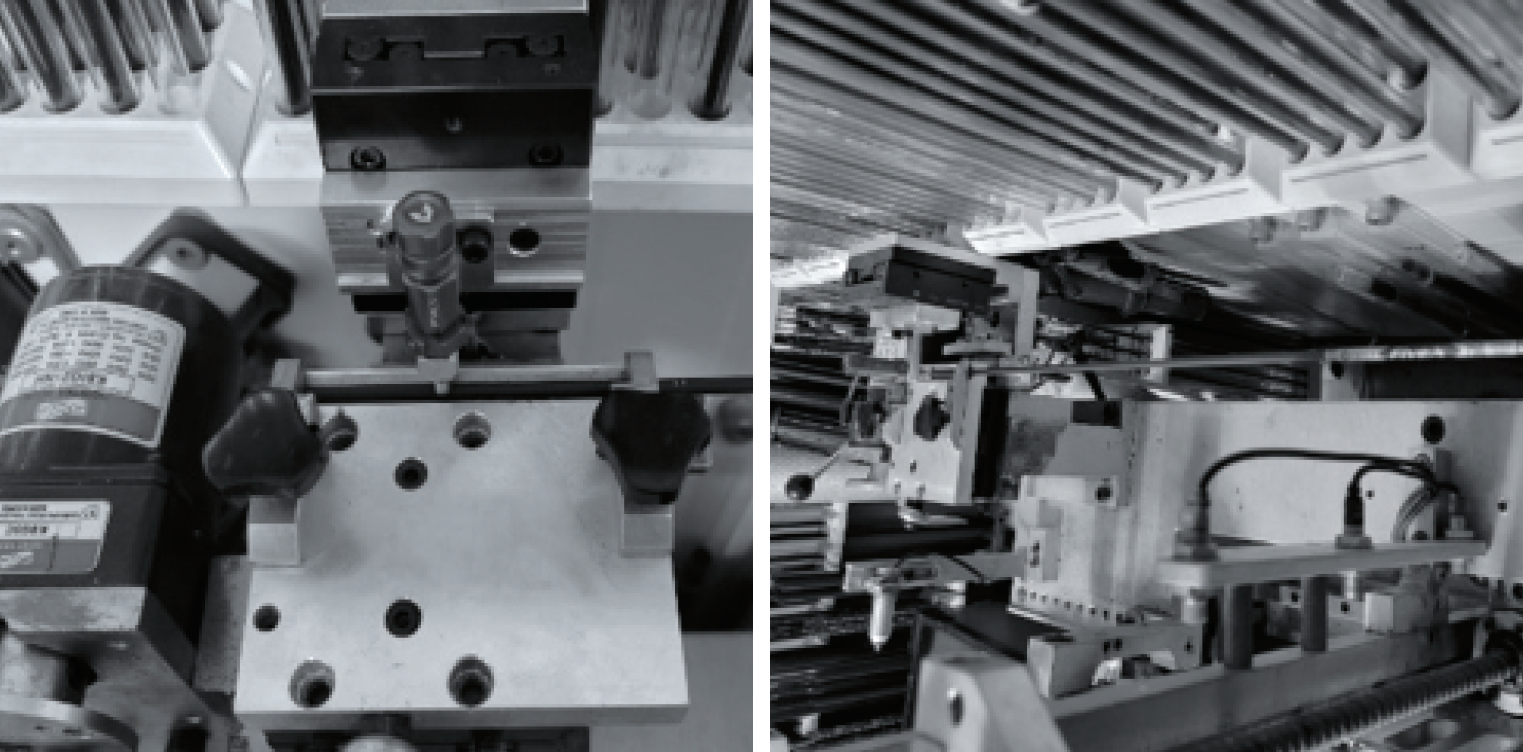

AR TECH - INNOVATIVE LIMBS CNC PROCESSING

AR technology maintains similar successful performance to limbs made with the original materials, while also utilizing CNC processing to increase the consistency and uniformity of productivity. Additionally, production of Fivics limbs eliminates any air in the adhesion process, minimizing limbs fractures and torsions. Lastly, the new 330-carbon improves the elasticity, optimizing speed and balance.

INSCREASED STIFFNESS WHILE SAVING THE SAME

STABILITY AND UNIFORM ELASTICITY OF THE LIMB.

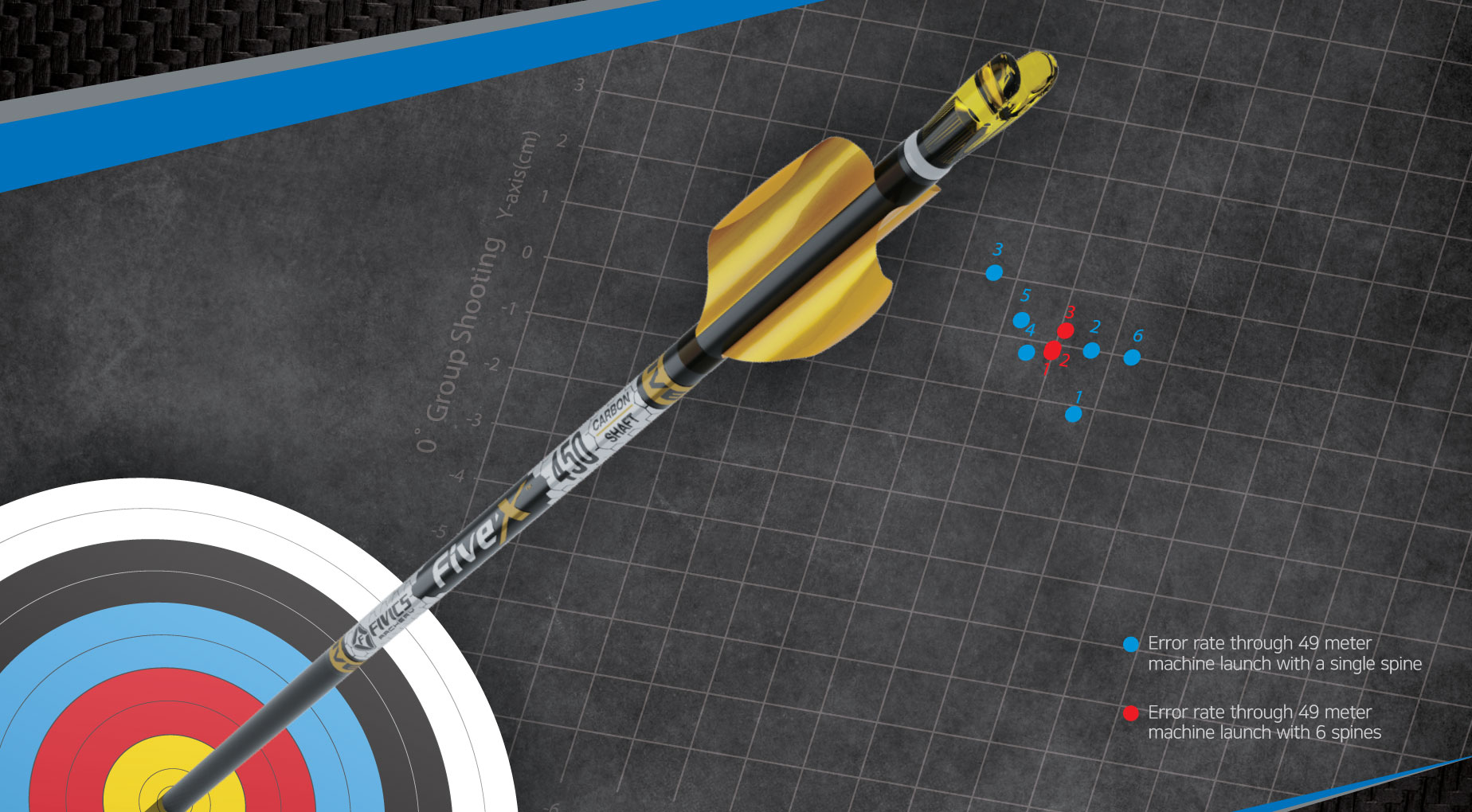

Produced with high quality and a special carbon technology for perfect arrow grouping.

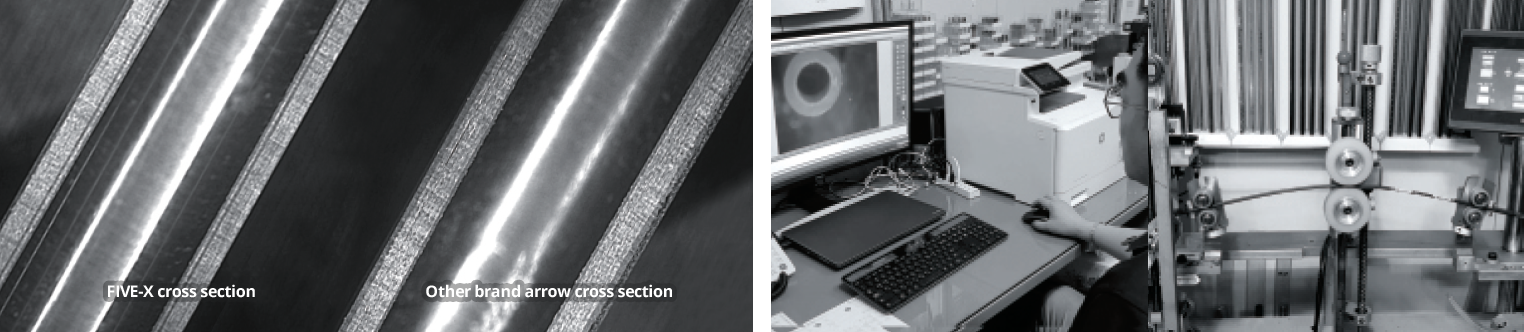

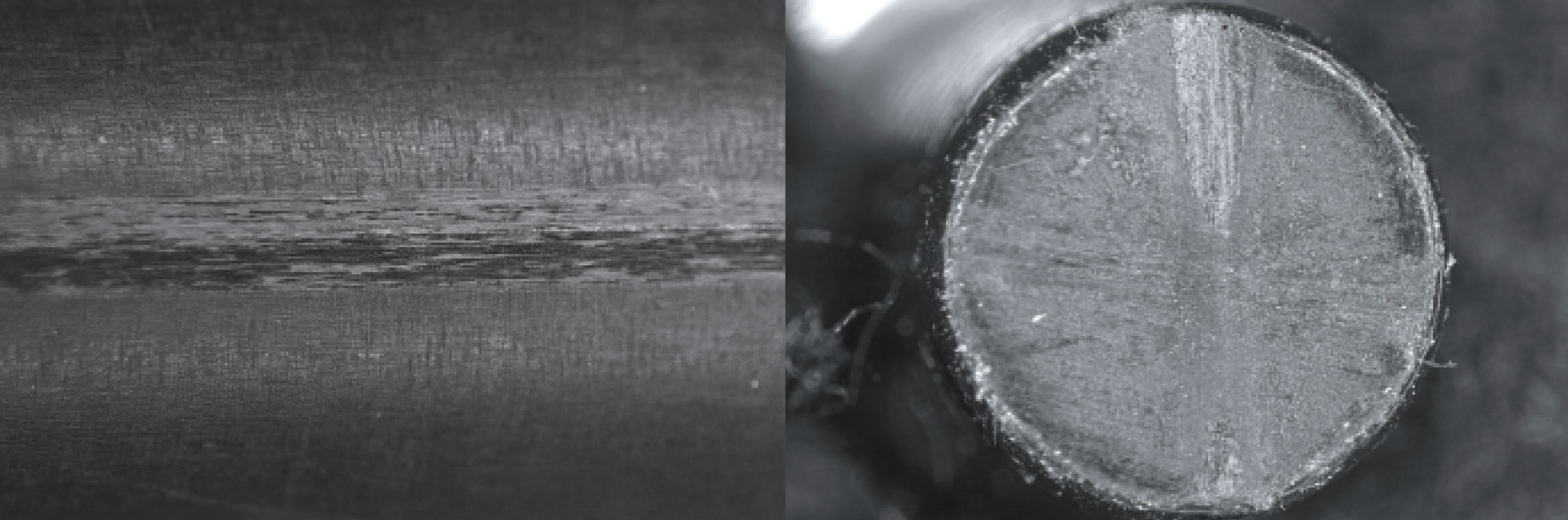

Arrow flight can be effected by carbon cracks inside the arrow.

Five-X reduces the chance of any cracks with a special high quality carbon material, allowing for the best arrow flight.

The FORNIX Stabilizer is efficiently layered by General Modulus Carbon into the High Modulus Carbon. This build is characterized as highly elastic and having a very strong spine relative to the weight of the unit. Fivics also uses the high-pressure mold method to diminish the presence of resins (foreign substances and impurities), maximize carbon purity density, and minimize residual and unwanted vibrations. The FIVICS specific DAMPER uses high-quality butyl as an ingredient to develop a mixing ratio which can reduce vibrations up to 100%.

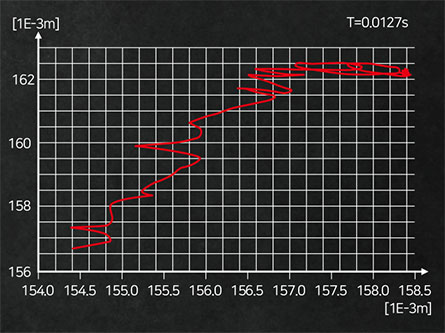

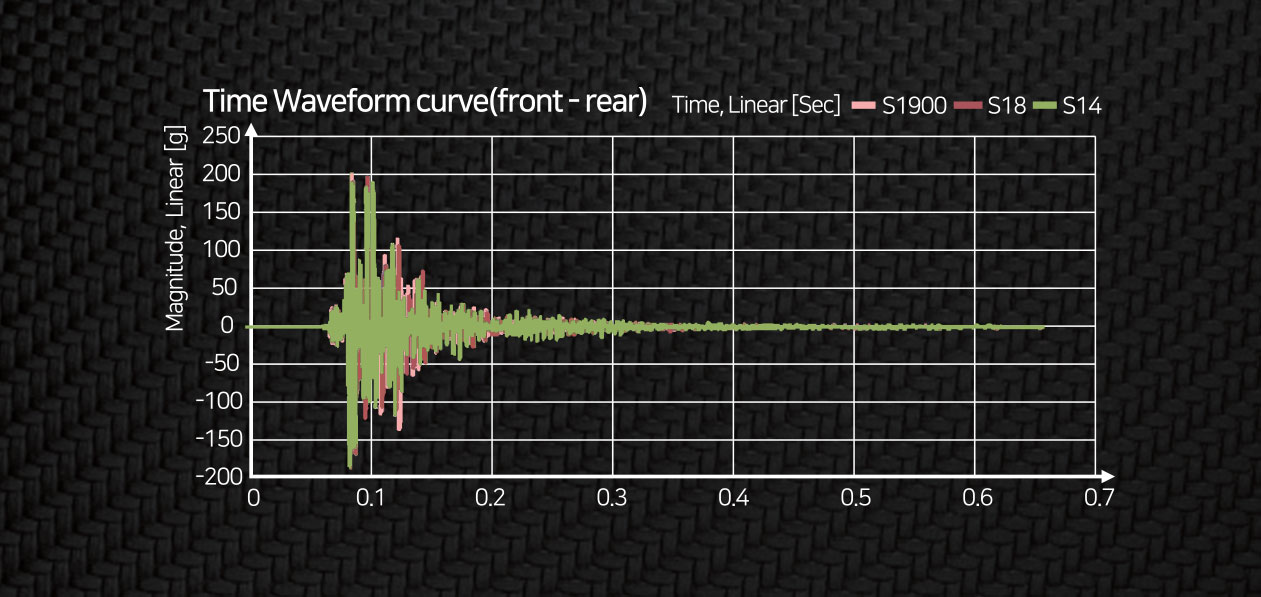

The Fornix 14, Fornix 18, and CEX1900 Stabilizers have been tested with the 3-axis acceleration test and the ultra-high-speed vibration tracking test, which proved the Fornix stabilizers have a superior carbon material and design compared to the CEX1900.

What is Hastealloy?

Hastealloy offers exceptional resistance to strong oxidizing solutions, strong durability in reducing environments, and a low carbon content that provides minimization of grain-boundary carbide precipitation.

What is Corrosion resistance?

Corrosion resistance refers to the resistance a material offers against a reaction with adverse elements that can corrode the material. Various materials have this property intrinsically, depending upon their corrosion resistance rate. Hastealloy minimizes corrosion when the arrow shaft touches the cushion plunger during arrow flight and makes the arrow fly more stable with greater grouping. We apply this high-end material to the new cushion plunger “Airex”.

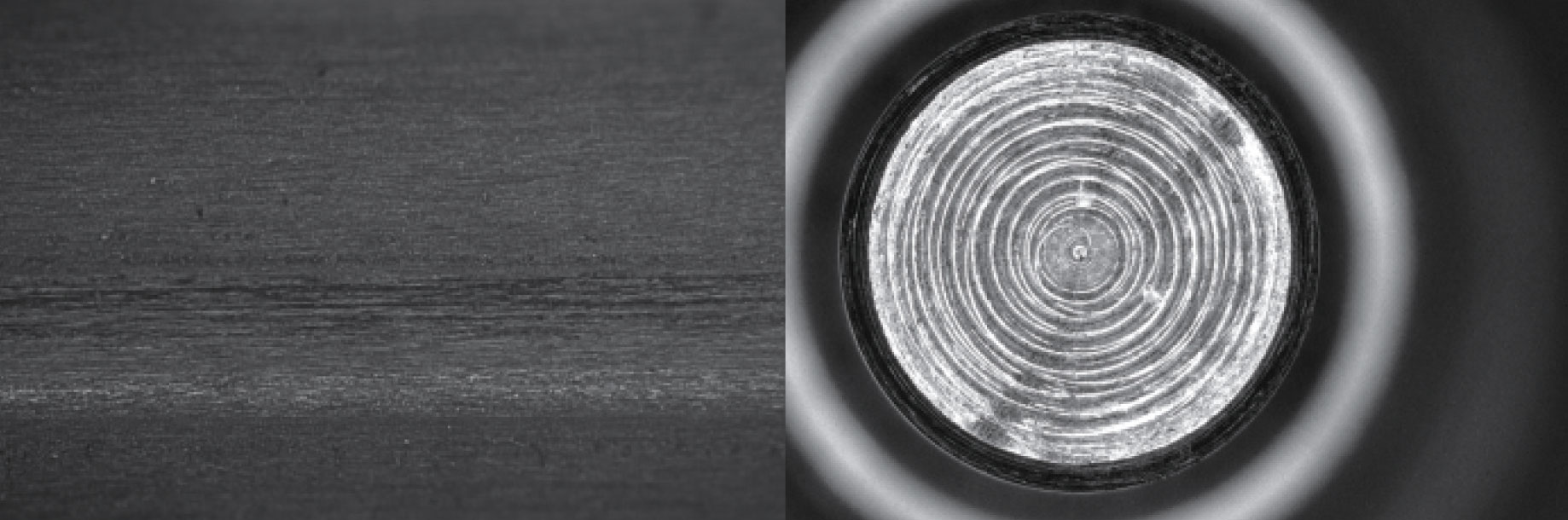

After installing on the cushion plunger test equipment, measurements of

the friction were taken 3 times for each material, repeated 2,000 times.

Measurements of the abrasion of the arrow surface and abrasion of

the pressure point per number of time were also collected.

Material 1: Hastealloy Pressure Point

Material 2: Aluminum Pressure Point

HASTEALLOY Pressure point

Arrow Shaft Surface / Pressure Point : 6000 times shot abrasion test

- Arrow Shaft Surface Abrasion : Almost None

- Pressure Point Abrasion : Almost None

ALUMINUM Pressure point

Arrow Shaft Surface / Pressure Point : 2000 times shot abrasion test

- Arrow Shaft Surface Abrasion : High

- Pressure Point Abrasion : High

아래의 사항을 참고해주세요